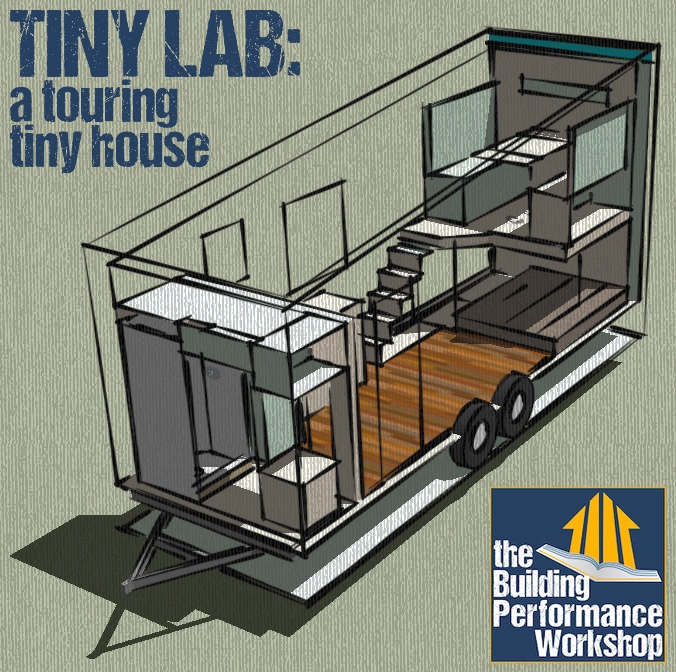

In #1: SHAPE AND LAYOUT, Corbett and Grace show the 3D sketchup model of the Tiny Lab, and bring engineer John Bergman in for some heavy lifting to do with pinpointing the center of gravity on this 24 ft trailer tiny house.

In #2: AIRSEALING, INSULATION, & WEATHER BARRIERS, tour the process of energy modeling the tiny house to determine the optimal R-values and level of airtightness, and hear about vapor barriers, moisture control, and drainage.

In #3: HEATING, COOLING, AND VENTILATION, you get a taste for how wrong a lot of the discussion goes about homes in general, and tiny homes especially. The HVAC design, including Manual J heat load calculations and hourly solar gain curves are analyzed and used for things as straightforward as deciding which direction to park the tiny house.

In #4: BELLS & WHISTLES, see behind the design of the solar PV kit, formaldehyde-free plywood built-ins, composting toilet, off-grid plumbing challenges, and luxury items that just add that quality of life that tiny house occupants are seeking.

We really hope you'll tune in for the videos of construction- you can subscribe to our YouTube channel right now with one click!